A Joint Innovation from KTS & Chemtex.

Executive Summary

The global demand for recycled PET (rPET) is rising rapidly as consumer brands and regulators set ambitious sustainability targets. Yet, despite decades of progress, most packaging applications have stalled due to inherent limitations in mechanical recycling methods & prohibitive costs of chemical recycling approaches.

PolyReVolve™, developed by KTS and Chemtex, introduces a breakthrough chemical recycling platform built on proprietary partial glycolysis innovations. By producing an optimized oligomer intermediate, PolyReVolve™ delivers significantly higher reactivity, vastly improved production capacities, and improved colour and product quality — all at a lower capital cost compared to alternative chemical recycling approaches.

This whitepaper outlines the market challenge, compares existing solutions, and presents the business case for PolyReVolve™ as the most viable pathway to closing the PET loop — particularly for high-growth markets like India and China.

1. Market Context: The Limits of Mechanical Recycling

The PET circular economy has been built primarily on mechanical recycling. Shredded, washed, and re-extruded PET flake (post-consumer resin, or PCR) serves as the backbone of most rPET supply chains. However, mechanical recycling faces inherent constraints:

- Quality degradation: Thermal degradation occurs with side reactions creating coloured compounds which remain in the polymer, yellowing the resin and limiting its use in high-performance packaging.

- Circularity Limits – Quality degradation is compounded through multiple product recycle loops limiting the true circularity of PET.

- Contamination risks: PVC, polyolefins, and non-food-grade inputs compromise final product quality.

- Regulatory limits: Food-contact approvals can restrict mechanical rPET content

- Supply imbalance: With global rPET demand projected to exceed 20 million tons by 2030, mechanical collection and sorting systems cannot keep pace.

As a result, the industry struggles to scale beyond partial substitution. Major brands face rising costs, reputational risk, and missed sustainability targets.

2. Technology Landscape: Current Chemical Recycling Options

While each approach offers promise, none have achieved cost-effective, scalable integration into mainstream PET supply chains. Most demand multiple hundreds of million dollars in greenfield capex per plant, an investment barrier for emerging markets

3. Introducing PolyRevolve™: A New Class of Chemical Recycling

PolyReVolve™ represents a new path forward in PET recycling, combining KTS’s proprietary innovations in reactor technology and partial glycolysis using Chemtex’s expertise in large-scale process deployment. Unlike conventional recycling pathways, PolyReVolve™ improves reactivity by producing optimized oligomer intermediates that unlock a step-change in both production capacity and product quality. The process uses readily available PET flake or PIW textile which is melted and partially glycolyzed followed by decontamination steps in industrially proven polymerisation reactors to make the desired polyester to meet the specifications for bottle and textile grade rPET.

Why It Matters

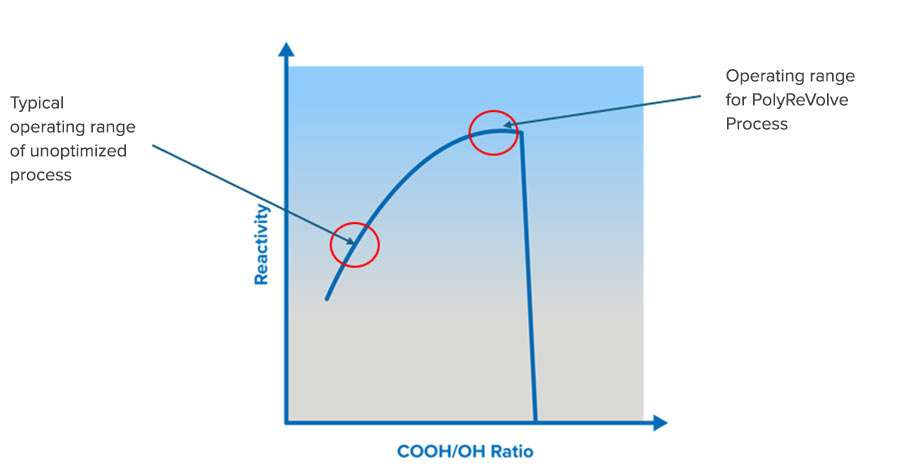

- Optimized oligomer chemistry: KTS’s IP ensures precise control over end group ratios, yielding oligomer blends that are significantly more reactive than those produced by simple glycolysis and other alternative methods. Achieving higher rPET content directly in the polymerisation reactors.

- Superior product quality: The optimized intermediates enable production of improved polymer, ensuring consistency and regulatory compliance for 100% food-contact\ applications.

- Scalable throughput: Enhanced reactivity translates directly into greater plant output, making PolyReVolve™ far more capital efficient for greenfield plants along with improving capacity for retrofits.

- A leap beyond mechanical recycling: Significant OpEx improvements compared to mechanical process are possible with this technology.

The KTS & Chemtex Advantage

- Decades of polyester innovation: KTS’s & Chemtex’s legacy in polyester provides unmatched process know-how and technical reliability with over 50 years’ experience leading the industry.

- Global scale-up expertise: Chemtex brings total engineering & project delivery experience, ensuring PolyReVolve™ can be deployed quickly and economically.

Together, this partnership has created a commercially viable, low CapEx, low OpEx solution that bridges the gap between mechanical recycling’s accessibility and chemical recycling’s purity.

4. Business Impact: Why PolyRevolve™ Matters

For PET to continue to grow sustainably as the material of choice, the industries using it need to exploit its fundamental capability as a recyclable polymer. Whilst technically possible via many routes, recycling will be driven at scale by economics.. PolyReVolve™ delivers compelling financial and operational benefits:

Cost Efficiency

- Reduced CapEx: Lower cost equipment with simple streamlined equipment sets making regional-scale plants (~50–150 KTA) feasible , avoiding mega-project risks but improving on mechanical’s scale

- Operational savings: Lower energy intensity when compared to alternative methods

- Feedstock Efficiency: Uses available PCR flake & Post-Industrial Waste (PIW), including textile PIW streams.

Polyester Producer Flexibility

- Applicable to retrofits & new builds

- Fully flexible recycled content capacity: Recycled to virgin ratio can be varied to meet market conditions. Tailored single stream capacity at virtually any scale.

- Adoptable as a side stream to virgin production

Improving Economics of Existing CP

- Capacity increases: For smaller existing CP units PolyReVolve can enable conversion to rPET without throughput losses

- Revive existing assets: The technology preserves profitability of existing small units that would otherwise be shutdown.

- Fast Investment Payback: Low capital retrofit with high returns.

- Product Opportunities: Enables high quality product for export markets and premium pricing

5. Next Steps: Partnering with KTS & Chemtex

PolyReVolve™ is ready for commercial deployment with strategic partners. KTS and Chemtex offer:

- Feasibility studies: Tailored assessments for producers seeking to evaluate integration at their facilities.

- Basic design package ready for deployment

Conclusion

The global PET value chain stands at a crossroads. Mechanical recycling alone cannot deliver the scale, quality or true circularity needed to meet brand commitments and regulatory demands. Meanwhile, traditional chemical recycling technologies remain prohibitively capital-intensive.

PolyReVolve™ offers a new path forward — a scalable, lower-cost, and technically robust solution that enables 100% rPET integration. Grounded in KTS’s & Chemtex’ polyester expertise and powered by proprietary oligomer chemistry, it represents not just a technology breakthrough, but a business imperative for the future of PET circularity.

To learn more or explore feasibility with PolyReVolve™, contact KTS & Chemtex.